From logistics to supply chain and logistic networks

LOGISTICS DEVELOPMENT

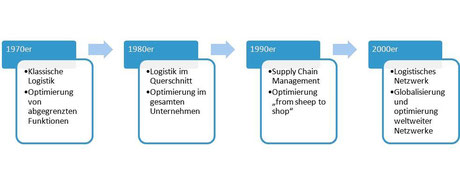

The emergence of logistics is closely tied to the history of business development and the optimization of supply chains. In the early days, companies organized their internal processes independently, leading to interface problems. To address these challenges, logistics was elevated within the corporate hierarchy with the task of coordinating and optimizing information and material flows across the organization.

Over time, the idea of emphasizing logistics further and leveraging optimization opportunities beyond company boundaries gave rise to Supply Chain Management. This encompassed the entire value chain "from sheep to shop," including all steps from raw material sourcing to the end consumer.

While the concept of holistic optimization of material flows made theoretical sense, it posed practical challenges. It was unclear which partner within the Supply Chain should be responsible for optimization, leading to questions about leadership distribution and revenue-sharing from theoretical overall optimization.

Furthermore, the Supply Chain concept carried potential pitfalls. To achieve optimization, companies needed to define the scope of their optimization space. This resulted in companies becoming essential components of the Supply Chain, making them non-interchangeable and potentially undermining competition, contrary to the original goal of the Supply Chain.

Due to the fact that companies often have various Supply Chains intersecting and overlapping, the concept of the logistical network emerged. Instead of focusing on global optimization, companies redirected their focus toward their own local optimizations. By combining local optimizations, they achieved satisfactory solutions, allowing them to remain interchangeable within the network and fostering competition among them. This, in turn, spurred innovation and contributed to sustainable business practices.

Logistics has evolved throughout history and is closely linked to the development of trade, transportation, and the modern economy. Here are some key milestones and dates related to the emergence of logistics:

- Antiquity (circa 3000 BC - 476 BC): In early civilizations such as ancient Egypt and Mesopotamia, systems for the storage and transportation of goods were developed. Inventory management and the organization of transportation were crucial for trade.

- Roman Roads (from around 300 BC): The Roman Empire built an extensive network of roads and aqueducts to efficiently transport goods and information. This infrastructure formed the basis for trade and logistics in Europe.

- Middle Ages (circa 500 - 1500): During the Middle Ages, trade routes like the Silk Road and the Hanseatic League played a significant role in the exchange of goods between East and West. The organization of trade caravans and ship convoys was crucial for the success of trade.

- Industrial Revolution (late 18th to early 19th century): The development of steam engines and railways revolutionized the transportation of goods. This led to more efficient logistics and enabled mass production and national and international trade.

- 20th Century: The proliferation of automobiles, the development of modern freight transportation, and the introduction of information technology contributed to further advancements in logistics. The use of containers and improvements in warehouse management technology significantly increased efficiency.

- Contemporary Times: Logistics has become a critical factor in the global economy. E-commerce and the global supply chain are part of the modern logistics system. The development of GPS and digital communication has greatly improved the tracking and control of the flow of goods.

These milestones represent significant stages in the development of logistics, closely intertwined with the evolution of trade, technology, and the global economy.